Тепловидение, профессиональные тепловизионные продукты и отраслевые решения

Thermal imaging principle

All objects with a temperature higher than absolute zero (-273.15°C, 0 K) will emit infrared radiation. The higher the temperature, the greater the radiation intensity. Thermal imaging usually uses the far infrared band of 8-14 microns. The infrared detector equipped with thermal imaging equipment can detect the intensity of infrared radiation of different wavelengths. Among them, the uncooled detector uses the thermoelectric effect or resistance change, which is usually used in portable thermal imaging equipment; the cooled detector requires a low-temperature working environment and has high sensitivity, which is suitable for high-precision scenes such as military and science.

The infrared detector converts the captured thermal radiation signal into an electronic signal. The intensity of the electronic signal is proportional to the temperature of the object. The electronic signal is digitized and the temperature data is mapped to different colors or grayscale values through a pseudo-color mapping algorithm, and finally a thermal map reflecting the temperature distribution of the object surface is generated.

Professional thermal imaging products

Handheld thermal imager

RE45 handheld temperature measurement thermal imager: using a 12μm uncooled infrared focal plane detector, 1280×1024 resolution imaging effect is good, suitable for power inspection, petrochemical monitoring, automatic control, fire monitoring, scientific research testing and other fields.

RE45L handheld temperature measurement thermal imager: pixel number 640×512, pixel pitch 12μm, focal length 8mm (F#1.0), field of view 55°×44°±5%, with Wifi/4G automatic upload to the cloud, TOF millimeter-level laser ranging function, temperature measurement range -20℃~550℃ (expandable to 650℃), mainly used in steel metallurgy, coal chemical industry, power grid, new energy and other fields.

RE60 series handheld infrared thermal imager: suitable for construction, electrical/mechanical, railway, steel petrochemical, new energy, photovoltaic, automation application and other industries.

Online temperature measurement infrared thermal imager

RE384 online temperature measurement infrared thermal imager: pixel number 384×288, pixel pitch 12μm, focal length 19mm (F#1.0), field of view 13°×10°±5%, mainly used in steel metallurgy, coal chemical industry, power grid, new energy and other fields.

RE652 online temperature measurement infrared thermal imager: It belongs to the G series short-wave high temperature infrared thermal imager, adopts high-performance short-wave infrared detector, and is suitable for ultra-high temperature measurement scenes, with a temperature measurement range of 600℃~2500℃.

RM-1 online temperature measurement movement: It is suitable for ultra-high temperature measurement application fields such as steel smelting, petrochemical, cement plant, furnace monitoring, etc.

Thermal imaging movement module

RM-55 high frame rate movement module: It is suitable for places that require high frame rate such as high-speed production line detection, aircraft detection, and high-speed rail detection.

10μm 5 million pixel uncooled infrared thermal imaging movement: Ultra-high pixel resolution, used with a telephoto lens, the image space pixel density is further improved, and the target recognition ability and distance are significantly enhanced.

120Hz uncooled infrared thermal imaging movement: While improving the frame rate, it further stabilizes the response rate and reduces ghosting, which is of great significance for high-speed moving scenes.

Other thermal imaging equipment

Dual-spectrum explosion-proof temperature measurement gun: suitable for temperature measurement applications such as petroleum and petrochemicals, coal, solid waste and hazardous waste, and hazardous chemical storage.

Silent-W series high-definition infrared panoramic radar: 360° no-dead-angle monitoring, real-time refresh of panoramic video images, and the farthest target detection distance of 8km, which can be used for panoramic monitoring in the field of intelligent Internet of Things.

Thermal imaging industry solutions

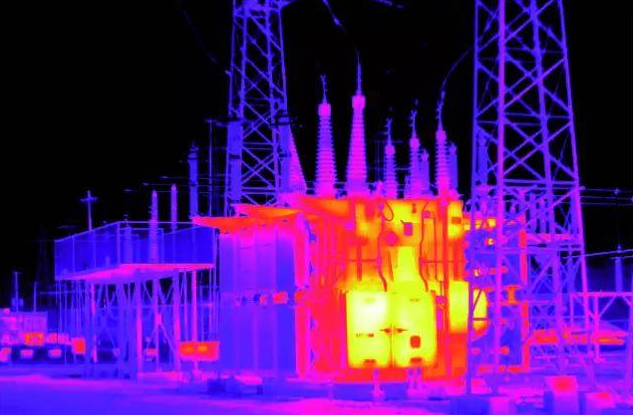

Electric power industry

Equipment inspection: Use handheld thermal imagers such as SAT Infrared's RE650 and RM-1 to conduct daily inspections of substation equipment, transmission lines, etc., and quickly locate hot spots and potential faults. The monitoring thermal imager RE650 can monitor key power facilities 24 hours a day, 7 days a week, and provide preventive maintenance suggestions.

Intelligent analysis: Through cloud servers and local data centers, advanced AI algorithms are used to intelligently analyze the collected temperature data to achieve fault diagnosis, trend prediction, and automatically generate inspection reports and maintenance suggestions.

Drone inspection: Equipped with drone thermal imagers such as RE650 and RM-1, the inspection efficiency, safety and accuracy of large power stations, transmission lines and other areas are improved.

Industrial manufacturing industry

Production process monitoring: In steel smelting, petrochemical and other production lines, online temperature measurement movements such as RE650 and RM-1 are used to monitor the furnace temperature and pipeline temperature in real time to ensure the stability and safety of the production process.

Equipment fault detection: Handheld thermal imagers can be used to detect the operating temperature of bearings, motors, reducers and other components of mechanical equipment, and timely discover hidden faults such as overheating and wear.

Quality inspection: During the product production process, thermal imaging detection can be used to detect defects and unevenness inside the product, such as the welding quality of plastic parts and the quality of welding points of electronic components.

Security monitoring industry

Perimeter prevention: Thermal imaging monitoring equipment is set up around airports, prisons, factories and other places to detect intruders or animals in time at night or in bad weather conditions, and realize perimeter prevention alarm.

Behavior monitoring: Thermal imaging technology can be used to monitor the behavior and activities of people. For example, in public places such as shopping malls and stations, thermal imaging can be used to analyze the flow and behavior of people, providing support for safety management and operations.

Fire rescue industry

Fire source detection: At the scene of a fire, thermal imaging equipment can quickly locate the source of the fire through the smoke, helping firefighters to develop fire-fighting strategies.

Personnel search and rescue: Thermal imagers can find the location of trapped people in a dark, smoky environment, improve search and rescue efficiency, and ensure the safety of rescuers.